CONCRETE NDT TESTING SERVICES

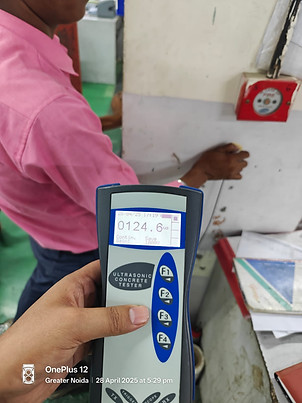

ULTRASONIC PULSE VELOCITY TESTING SERVICES

Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing (NDT) method for quality control of concrete materials, and detecting damages in structural components. The UPV methods have traditionally been used for the quality control of materials, mostly homogeneous materials such as metals and welded connections. With the recent advancement in transducer technology, the test has been widely accepted in testing concrete materials. Ultrasonic testing of concrete is an effective way for quality assessment and uniformity, and crack depth estimation. The test procedure has been standardized as the “Standard Test Method for Pulse Velocity through Concrete” An ultrasonic pulse velocity test is Nondestructive test to check the quality of concrete and natural rocks. In this test, the strength and quality of concrete or rock is assessed by measuring the velocity of an ultrasonic pulse passing through a concrete structure or natural rock formation. This test is conducted by passing a pulse of ultrasonic through concrete to be tested and measuring the time taken by pulse to get through the structure. Higher velocities indicate good quality and continuity of the material, while slower velocities may indicate concrete with many cracks or voids. Ultrasonic testing equipment includes a pulse generation circuit, consisting of electronic circuit for generating pulses and a transducer for transforming electronic pulse into mechanical pulse having an oscillation frequency in range of 40 kHz to 50 kHz, and a pulse reception circuit that receives the signal. The transducer, clock, oscillation circuit, and power source are assembled for use. After calibration to a standard sample of material with known properties, the transducers are placed on opposite sides of the material.

REBOUND HAMMER TESTING SERVICES

Rebound Hammer test is a Non-destructive testing method of concrete which provide a convenient and rapid indication of the compressive strength of the concrete. The rebound hammer is also called as Schmidt hammer that consist of a spring controlled mass that slides on a plunger within a tubular housing. When the plunger of rebound hammer is pressed against the surface of concrete, a spring controlled mass with a constant energy is made to hit concrete surface to rebound back. The extent of rebound, which is a measure of surface hardness, is measured on a graduated scale. This measured value is designated as Rebound Number (rebound index). A concrete with low strength and low stiffness will absorb more energy to yield in a lower rebound value.The hammer measures the rebound of a spring-loaded mass impacting against the surface of a sample. The test hammer hits the concrete at a defined energy. Its rebound is dependent on the hardness of the concrete and is measured by the test equipment. By reference to a conversion chart, the rebound value can be used to determine the concrete's compressive strength. When conducting the test, the hammer should be held at right angles to the surface, which in turn should be flat and smooth. The rebound reading will be affected by the orientation of the hammer: when used oriented upward (for example, on the underside of a suspended slab), gravity will increase the rebound distance of the mass, and vice versa for a test conducted on a floor slab. Schmidt hammer measurements are on an arbitrary scale ranging from 10 to 100.

CORE CUTTING SERVICES

A core cut is necessary to:Examine the roofing system for moisture and determine how much is present.Determine the types and characteristics of the existing roofing materials.Complete a thorough roofing survey.Assess the structural integrity of the roof deck. Metal corrodes. Concrete spalls. It’s important to determine if deck replacement or preparation is needed.Determine the type of roofing project your contractor will execute. A core cut will reveal whether a recover is possible (is there already two roof systems in place?) or if partial tear-off or a total reroof is necessary..Core drilling is a type of service in which a drill is used to remove a cylinder of material, called a ‘core.’This type of concrete cutting is used in many applications, including but not limited to:Walls, floor slabs, and ceilings for electrical and communication services, cabling, plumbing, or HVAC Slab and roadway holes for doweling drilling, rebar tie-ins, or drainageRecessed lighting and fixturesSampling and analysis of material.Most often, core cuts are taken when the building owner or facility manager wants to have work performed on the roof. More information is needed by the roofing contractor before the project can be determined and scope of work planned. This can help develop an accurate estimate and prevent unexpected expenditures due to unforeseen conditions as the project progresses.

SCAN BEFORE YOU CORE.

Penhall uses Rebar Locator technologies to detect TMT in concrete Structure before you cut or core, keeping projects on track and personnel safe

FERRO/REBAR SCANNING SERVICES

Ferro scanning, also known as rebar scanning or concrete scanning, is a non-destructive testing method used to locate and map embedded metallic elements, primarily steel reinforcement (rebar) and post-tension cables, within concrete structures. This technique is crucial for assessing the internal structure of concrete, especially before drilling, cutting, or coring, to avoid damaging critical components.

Here's a more detailed explanation:

Purpose: Ferro scanning helps determine the location, depth, and orientation of reinforcement steel within concrete.

How it works: It utilizes ground-penetrating radar (GPR) or electromagnetic induction technology to create a detailed map of the embedded metal.

Applications:

Safety: Prevents accidental damage during construction, renovation, or demolition by identifying the location of rebar, post-tension cables, and other embedded metal.

Structural assessment: Provides valuable information for assessing the condition of existing structures, especially older buildings without accurate drawings.

Quality control: Ensures proper placement of reinforcement during construction.

Planning: Helps engineers and contractors make informed decisions about drilling, cutting, and coring.

Benefits:

Non-destructive: It doesn't damage the concrete structure.

Accurate: Provides detailed information about the internal structure.

Cost-effective: Prevents costly damage and repairs.

CARBONATION TESTING SERVICES

A carbonation test in concrete assesses carbonation depth using a phenolphthalein indicator solution, which turns pink in alkaline (uncarbonated) concrete and remains colorless in carbonated (non-alkaline) areas. The measurement is taken by spraying the solution onto a freshly fractured or sawcut concrete surface, with the demarcation between pink and clear zones indicating the carbonation front. This depth is critical for evaluating reinforcement corrosion risk, as carbonation reduces concrete's protective alkalinity.

Purpose

-

Determine carbonation depth:

The primary goal is to measure the depth to which carbon dioxide (CO2) has penetrated the concrete.

-

Assess corrosion risk:

Carbonation lowers the pH of concrete, causing it to lose its ability to passively protect embedded reinforcing steel, which can lead to corrosion.

Procedure

-

Prepare the surface:

Expose a fresh, uncarbonated concrete surface by fracturing or sawing a piece of concrete. A smooth surface is important to avoid misleading results.

-

Apply the indicator:

Spray the concrete surface with a 1% phenolphthalein indicator solution. The solution is often made by dissolving phenolphthalein in a solvent like isopropyl alcohol.

-

Observe the color change:

-

Pink/Purple color: Areas that turn a pinkish-purple color indicate a pH above 8.6, meaning the concrete is still sufficiently alkaline.

-

Colorless areas: Where the solution remains colorless, the concrete has a pH below 8.6 and is considered carbonated.

-

-

Measure the depth:

The line or front where the color changes from pink to clear indicates the depth of carbonation. Measurements are taken on the exposed face.

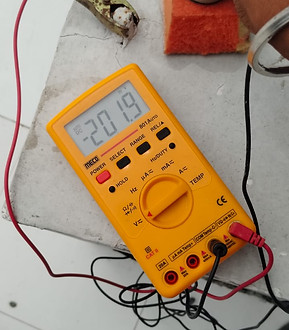

HALF-CELL POTENTIAL TESTING SERVICES

A half-cell potential test is a non-destructive method used to assess the risk of corrosion in steel reinforcing bars within concrete structures. It involves measuring the electrical potential difference between the reinforcing steel and a reference electrode placed on the concrete surface, with the results used to map areas of potential corrosion. The test is conducted according to standards like ASTM C876 and helps in planning maintenance and ensuring structural durability.

How the test works

-

An electrical connection is made to the reinforcing steel, typically through a data-logging voltmeter.

-

The other terminal of the voltmeter is connected to a reference electrode, most commonly a copper-copper sulfate half-cell.

-

The porous plug of the half-cell is wetted and pressed against the concrete surface to ensure electrical contact.

-

Readings are taken at regular intervals across the concrete surface.

-

By plotting the potential readings, a "corrosion map" can be created to identify areas with a higher probability of corrosion.

What the results mean

-

The potential difference is correlated with the likelihood of corrosion.

-

Lower potential values indicate a lower risk of corrosion, while more negative values suggest a higher risk.

-

A common interpretation is that a potential below

-200 mV indicates a low risk of corrosion (less than 10%), while more negative values indicate a higher probability.

Importance and limitations

-

This test is a key tool for monitoring the long-term health of reinforced concrete structures, as it is non-destructive and can be performed at any point in the structure's life.

-

It helps engineers predict which areas may need maintenance before corrosion becomes severe, which is crucial for extending the structure's lifespan.

-

The test can be sensitive to weather conditions, and it is often most reliable on moist concrete surfaces.

-

It is often used in conjunction with other tests, such as those for chloride content, to provide a more complete picture of the corrosion status.